From Linear to Circular

New Delhi, August 31. Marc Goldschmidt, Vice President of Remanufacturing & Overhaul Technologies at the Rolls-Royce business unit Power Systems, talks about how striving to enable a circular economy delivers benefits for our environment and our customers.

New Delhi, August 31. Marc Goldschmidt, Vice President of Remanufacturing & Overhaul Technologies at the Rolls-Royce business unit Power Systems, talks about how striving to enable a circular economy delivers benefits for our environment and our customers.

How the right approach increases sustainability and reduces costs

No matter which industry or sector we look at around the world, the goal is the same everywhere: growth. Our customers and partners rely on our solutions to deliver the performance they need to develop and grow their businesses. At the same time, the need and demand for greater sustainability is growing across all industries.

Our solutions are already meeting this demand through alternative fuels like hydrotreated vegetable oil (HVO), Selective Catalytic Reduction (SCR) systems and optimised technologies inside the engine, to name just a few examples.

But as a comprehensive solution provider, we want to think beyond just the emissions output of our products. Our offering, which covers the entire life cycle of our engines and systems, can also help increase sustainability and help shape a liveable future for all.

A key factor here is to move away from the throwaway mindset and talk more about remanufacturing and reusing. Or, to say it in other words, we need to use circular, rather than linear economy.

More circulation means more sustainability

Reusing products and resources is not limited to industries; it’s a concept we’re all familiar with in our daily lives. In Germany, where our Power Systems headquarters is based, glass bottles are collected, including a deposit system, and recycled at their end of life by melting them down and using the material to create new packaging, resulting in reduced energy costs and a decreased demand for raw materials. The potential for reuse is vast, and by embracing this practice, we can make a meaningful contribution to sustainability.

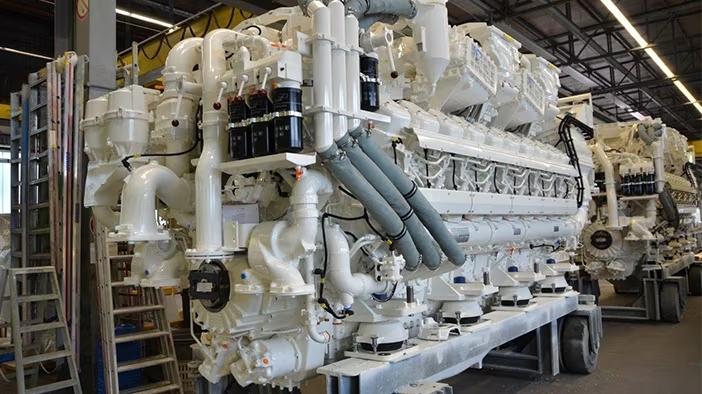

So, the idea naturally comes to mind that for heavy industries, we should also think about how to integrate similar systems and effects. Regardless of the application for which they are intended, our engines consist of hundreds and thousands of parts that are manufactured and assembled with the highest precision before they leave one of our factories. For each new engine, of course, new raw materials are needed. Nevertheless, there are ways and means to make this process more sustainable in the long term, such as through our Remanufacturing and Overhaul portfolio.

A second life for engines full of power

At Rolls-Royce, we are running a circular economy instead of a linear economy in our operations. The latter would mean that we would manufacture a new engine from raw materials, which would simply be disposed of after its operational life, after which the customer would need a new product.

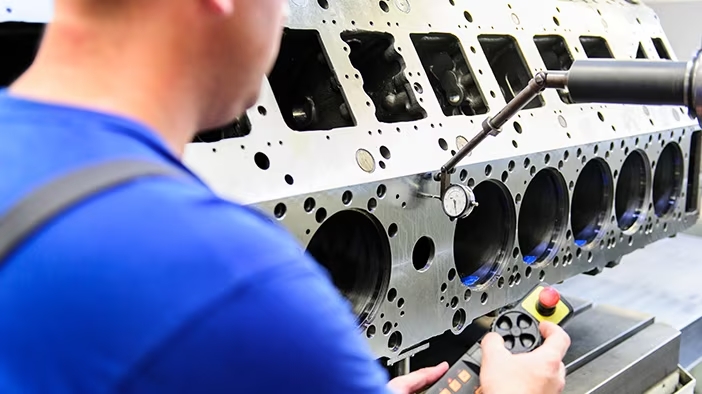

Instead, we give all our products second, third and even fourth chances by overhauling them. The entire product is disassembled into its individual parts, cleaned all around, each piece is checked for damage or wear and replaced with brand-new parts only if necessary. The result is a product that is as good as one fresh off the assembly line, performs like new, and of course, offers the same reliability as a new product.

With fewer resources, time and emissions, we can turn our products into like-new engines at the end of their life. Instead of throwing away, we renew. To keep this cycle alive, a deposit is included in the price of our products. Customers can reclaim this deposit when they return their equipment to us at the end of its life cycle. Alternatively, in order to minimise downtime in their operations, they can also exchange their existing engine or system for a remanufactured one.

We’re by no means just talking about the modern systems that are now part of our portfolio. In plants such as the one in Duisburg, Germany, we also overhaul classic engines, some of which have been in operation for 30, 40 or even 50 years and have undergone several overhauls. In this way, we not only ensure optimum operational conditions for long-standing customers and their equipment that has been in operation for a significant period of time but also extend our circular economy to the engines that have been in use for the longest number of years.

Benefits for the environment and customers

One of the biggest benefits of a circular economy is greater sustainability for industries that typically emit large amounts of emissions. It is the natural and logical consequence of our striving to deliver the same reliability and performance that people have come to expect from our products, while at the same time making the operation, production and now the overhaul of our engines better for the environment. Of course, this also creates monetary incentives for customers to support a circular economy, especially through the deposit system and trade-ins.