General Atomics Completes SiGA Cladded Nuclear Fuel Rod Irradiation Testing

SAN DIEGO. General Atomics Electromagnetic Systems (GA-EMS) announced on December 4 that, unfueled nuclear fuel rods using the company’s SiGA® fuel cladding successfully survived a 120-day irradiation testing period in the Advanced Test Reactor (ATR) located at Idaho National Laboratory. Testing was conducted to validate the robustness and integrity of the SiGA cladding after exposure to high neutron flux in a pressurized water reactor environment. Following the test, SiGA cladded rods remained intact and showed no significant mass change, indicating promising performance. More detailed examinations are underway to further evaluate post-test data to validate individual rod integrity to remain gas-tight, with no evidence of degradation, leaking, or structural change.

“The testing results offer critical, quantifiable, and independent validation that our SiC cladding technology is on the right path to provide a safe, suitable, accident tolerant fuel cladding solution for the nuclear fleet,” said Scott Forney, President of GA-EMS. “This success is a key milestone on SiGA cladding’s development path to enhance the safety of the existing US fleet of light water reactors, particularly during an unlikely event of an accident. It could also do the same for the future generation of advanced nuclear power systems.”

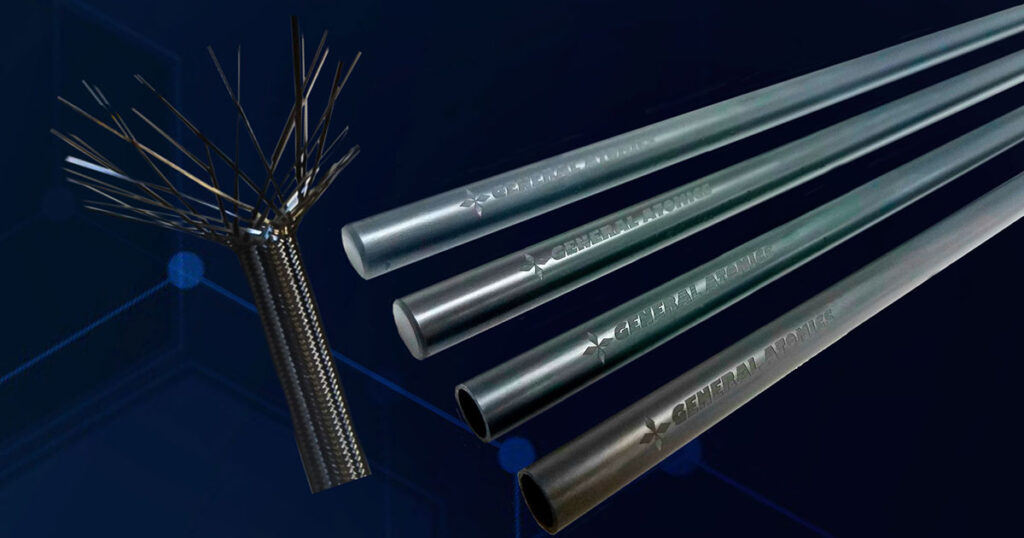

SiGA is a silicon carbide (SiC) composite material that forms the basis for the development of nuclear reactor fuel rods that can survive temperatures far beyond that of current materials. SiGA’s multi-layered SiC composite cladding structure is sealed with a fully-SiC joining process, enabling exceptional stability during operational temperature cycling. This material provides greater stability and safety at temperatures up to 1900° C, well beyond that of metal fuel rod claddings. SiGA cladding would also enable higher powers and longer fuel lifetimes, thereby enhancing overall reactor performance and economics. GA-EMS has been under contract with the Department of Energy (DOE) to support the Accident Tolerant Fuel Program and advance GA-EMS’ silicon carbide fuel cladding technology for future deployment in US nuclear reactors.

“We look forward to continuing our partnership with the DOE and the national labs to accelerate the irradiation testing to demonstrate the performance of fueled SiGA cladded rods. The planned test series progressively builds up performance data to show that SiGA cladding can effectively contain the fuel and any gasses that are produced when subjected to irradiation and high temperature,” said Dr. Christina Back, Vice President of GA-EMS Nuclear Technologies and Materials. “In parallel, we are scaling up to full size, 12-foot long SiGA rods and will then be doing the irradiation testing in actual commercial reactors with deployment targeted for the mid-2030 timeframe. We remain committed to bringing SiGA’s unique safety and efficiency benefits to the nation’s nuclear fleet.”