|

The

A400M has the capability to fly distances up to

4,700 nm / 8,700 km, at a cruising altitude of

up to 37,000 ft, and at a speed of up to Mach

0.72, very similar to that of a jet liner. This

gives it the potential for strategic/logistic

missions. Flying faster and higher, it can respond

more rapidly to crises, because greater distances

can be flown in a one crew duty day. The

A400M has the capability to fly distances up to

4,700 nm / 8,700 km, at a cruising altitude of

up to 37,000 ft, and at a speed of up to Mach

0.72, very similar to that of a jet liner. This

gives it the potential for strategic/logistic

missions. Flying faster and higher, it can respond

more rapidly to crises, because greater distances

can be flown in a one crew duty day.

The new aircraft is hence regarded as much more

efficient than its predecessors. Also, as it can

fly higher, it can cruise above turbulence, resulting

in less fatigue for the crew and passengers or

troops alike.

Addressing a group of international journalists

recently during a Trade Media Briefing at Sao

Paulo, Seville, Spain, Rafael Nogueras Cebrero,

Head of A400M Final Assembly Line and Flight Test

Centre, announced that the production of first

customer aircraft MSN 7 had been launched and

will be on the FAL by the end of 2011. Eight countries,

eight operators and 184 aircraft are providing

a strong customer base for a smooth start of the

production line.

A400M can perform missions which previously required

two - or more - different types of aircraft, and

which even then provided an imperfect solution.

Its fuselage’s external width of 5.64 metres

/ 18 ft 6 in is equal to that of the A330/A340

wide-body. The inside usable width of four metres

/ 13ft, height of up to four metres / 13ft, and

usable length of nearly 18m / 59ft, allows it

to carry numerous items of outsize cargo including,

for example, an NH90 or a heavy lift CH-47 Chinook

helicopter, or two Stryker infantry carrier vehicles

(ICV) for military purposes.

It

can also carry a semi-articulated truck with a

6m / 20ft container, or a rescue boat, or large

lifting devices, such as excavators or mobile

cranes needed to assist in disaster relief, informed

Rafael. It

can also carry a semi-articulated truck with a

6m / 20ft container, or a rescue boat, or large

lifting devices, such as excavators or mobile

cranes needed to assist in disaster relief, informed

Rafael.

Furthermore, the A400M is the only airlifter

that can fly these items directly to the site

of action thanks to its unique landing characteristics.

With its 12- wheel main landing gear designed

for operations from stone, gravel or sand strips,

its efficient absorption of shock-loads into the

airframe structure, and its minimised risk of

foreign object damage, the A400M is able to land

on, and take-off from, short, soft and rough unprepared

airstrips meeting the CBR6 standard.

Once on the ground, the A400M is designed for

very rapid and autonomous cargo unloading or loading

without any specialized ground support equipment.

Equipped with on-board winches and a crane, the

cargo hold is optimised for single loadmaster

operation from a computerised workstation, where

the loadmaster can pre-plan loading from a loads

data base. So, by minimising the time on the ground,

the A400M’s systems also reduce the aircraft’s

vulnerability to hostile action.

Being able to fly at higher altitudes and faster,

it can also be configured into a tanker aircraft

to refuel military fast jets (fighters) and other

large aircraft at speeds of up to 300kt indicated

air speed (IAS) at 25,000ft. But because of its

low speed performance, it can equally well refuel

helicopters at 110kt up to 5,000ft.

Refuelling can be done either through two wing-pod

hoses or through a centre-line fuselage refuelling

unit. Its built-in air-toair refuelling capability

allows it to be rapidly re-configured to become

a tanker. It can therefore be easily adapted to

rapidly changing operational scenarios, being

able to perform very different types of missions,

as needed. The aircraft itself can also be refuelled

in flight.

A400M has been specifically designed for low

detectability, low vulnerability and high survivability,

giving it excellent self-protection. With clean

and minimised infra-red signature engines, highly

responsive fly-by-wire flight controls, four independent

control computers, comprehensive defensive aids,

cockpit armouring and damage tolerant controls,

the A400M is hard to find, hard to hit and hard

to kill. As for its “down-time”, the A400M is

conceived to be what the ccompany says “the most

reliable airlifter ever.”

It needs only 84 days of scheduled downtime maintenance

in 12 years, Rafael informed India Strategic.

The nations in the project, which is otherwise

delayed, include Belgium, France, Germany, Italy,

Luxemburg, Portugal, Spain, Turkey, and the United

Kingdom.

Meanwhile, the aviation manufacturers of these

countries have also started working on the concept

of a new military transport under the designation

of “Future Large Aircraft” (FLA).

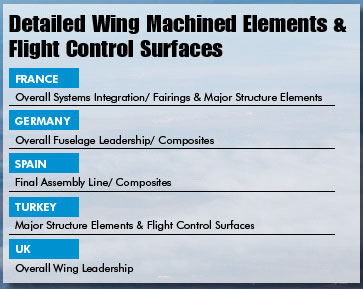

They

involve Aerospatiale in France, Deutsche Aerospace

(DASA) in Germany, British Aerospace in the UK,

CASA in Spain, the industries of Belgium and Luxemburg

which joined forces under the FLABEL grouping,

as well as Alenia in Italy, OGMA in Portugal,

and the Turkish Aerospace Industry (TAI) in Turkey. They

involve Aerospatiale in France, Deutsche Aerospace

(DASA) in Germany, British Aerospace in the UK,

CASA in Spain, the industries of Belgium and Luxemburg

which joined forces under the FLABEL grouping,

as well as Alenia in Italy, OGMA in Portugal,

and the Turkish Aerospace Industry (TAI) in Turkey.

An initial call for tender was launched by the

European Nations in 1998, to which the FLA grouping

responded in 1999. After thorough examination

of the various options which included other existing

products and even co-operation with nonwest- European

manufacturers, the FLA proposal was selected by

these countries in July 2000. The initial commitment

was for 288 aircraft from all the eight countries.

On 21st December 2001, an initial contract was

signed for a total of 197 A400Ms, as the aircraft

was to be called from then on, by the European

nations, but without Italy which had withdrawn

from the launch-nations group. The German order

for 73 aircraft was subject to hand-written budget

approval, which was eventually obtained at the

beginning of 2003, but for only 60 aircraft.

Meanwhile, Portugal had also withdrawn from the

initial group. The final contract for 180 aircraft

was signed with OCCAR, representing Belgium, France,

Germany, Luxemburg, Spain, Turkey, and the UK

on 27th May 2003. This was to be followed by an

order for four by Malaysia in December 2005.

Orders which stand to date are total 184 from

8 countries (Germany 60, France 50, Spain 27 ,UK

25,Turkey 10, Belgium 7 and Luxemburg 1. Malaysia

has ordered four of these and is the only Asian

client yet).

The A400M can also very easily be converted into

an aerial refuelling tanker. Because all provisions

are built into the airframe, it takes under two

hours to convert the A400M from an airlifter into

a two-point tanker aircraft. Hard points, fuel

lines and electric connections are already built

into the wings. The two refuelling pods under

the wing can provide a fuel flow of up to 1,200

kg / 2,645lb per minute. The centre-line fuselage

refuelling unit provides a fuel flow of some 1,800

kg /3,968 lb per minute. Three video cameras can

be installed if desired, to monitor the refuelling

from the wing pods and the centreline unit.

The A400M carries up to 64,000 litres /14,078gallons

of fuel in its wings and centre wing box. Two

additional cargo hold units can also be installed,

providing an additional 7,200 litres /1,583 gallons

of fuel each.

The fuel carried in the extra tanks can be of

a different nature to the fuel in the main tanks.

This enables the A400M to cater for the needs

of different types of receiver aircraft. Also,

because of its low fuel consumption, the A400M

can do a 4-hour mission while off-loading some

35 tonnes /78,400 lb of fuel. Larger aircraft

can also be refuelled by the A400M.

Rafael

said that the A400M is the only tanker which can

refuel the entire range of military aircraft at

their preferred speeds and altitudes. This is

because it can fly both at the low speeds and

altitudes (105 to 115 kt) typically required to

refuel helicopters, as well as at speeds of 280

to 300 kt and altitudes of around 25,000 ft which

are typical for fast jets, such as fighters or

large aircraft. Rafael

said that the A400M is the only tanker which can

refuel the entire range of military aircraft at

their preferred speeds and altitudes. This is

because it can fly both at the low speeds and

altitudes (105 to 115 kt) typically required to

refuel helicopters, as well as at speeds of 280

to 300 kt and altitudes of around 25,000 ft which

are typical for fast jets, such as fighters or

large aircraft.

The A400M can accommodate up to 116 troops sitting

face to face, alongside the fuselage and backto-

back along the centre line of the aircraft. Its

wider fuselage which provides more space between

the rows, it can carry the same number of fully

equipped paratroopers with their chutes and related

equipment. They can be dropped in less time over

a limited area, allowing them to swiftly regroup

and to be quickly operational.

But above all , the A400M permits two paratroopers

to jump simultaneously either through the cargo

door or through the two lateral doors. Special

forces can also be dropped from altitudes as high

as 40,000 ft.

Another key feature of the A400M is its computerized

“fly-by-wire” flight controls already widely used

on other civil transport aircraft, starting with

the A320. Replacing the conventional cables and

pulleys by electrical wires linked to four independent

flight control computers which send signals to

actuators, not only reduces weight, but also maintenance

time. This also gives a much greater precision

to the commands. The fly-by-wire controls permit

the implementation of “flight envelope protection”

which, by preventing the aircraft from stalling,

allows the pilot to achieve optimum performance

in a critical escape manoeuvre by simply pulling

the full stick back. The fly-by-wire system then

manages the whole aircraft configuration accordingly,

without the pilot having to intervene.

One of the key elements to ensure the versatility

of the A400M was the selection for the aircraft

of an allnew, specifically designed three-shaft

turboprop engine with eight bladed propellers.

The 11,000 shp TP400 developed by EuroProp International

(EPI), a consortium comprising Rolls Royce, Snecma,

MTU and ITP, is the most powerful turboprop ever

built.

Ed Strongman, the Chief Test Pilot Airbus Military

told India Strategic that till 19thMay 2010, the

A 400M had undergone 43 test flights and 165 hours

of flying. He also said that an initial problem

of the brakes had been rectified to achieve perfect

landing.

The aircraft’s flight campaign is progressing

well at two Flight Test Centres at Touluse in

France and at Seville, said Strongman.

|